Navigating Global Backpack Manufacturing: Why China Still Leads

When it comes to manufacturing backpacks, there are several countries to consider, each with its unique strengths. While China remains a dominant force in the industry, other countries like Vietnam, Bangladesh, and India also offer compelling advantages. Here’s an overview of key manufacturing hubs and why China continues to stand out:

1. China: The Established Leader

China’s long-standing leadership in backpack manufacturing is supported by several factors:

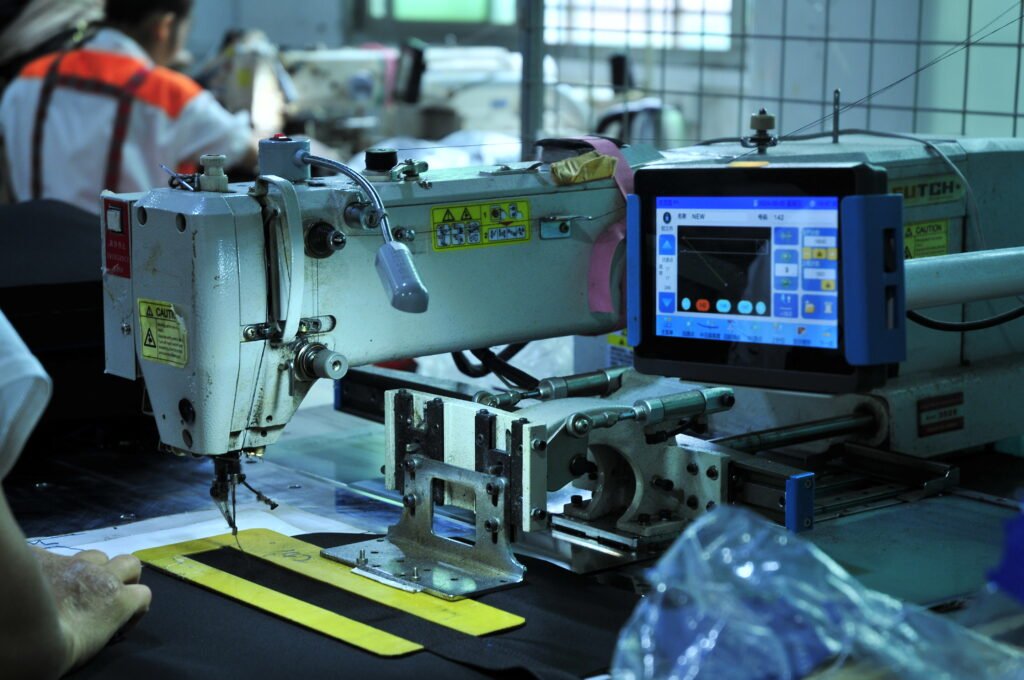

- Advanced Facilities and Expertise: China boasts state-of-the-art machinery and a highly skilled workforce, providing precision and efficiency in production.

- Cost Efficiency: The relatively lower labor costs and economies of scale in China help keep production costs competitive.

- Diverse Material Options: From premium leathers to innovative eco-friendly fabrics, China offers a broad range of materials to suit various needs.

- Strong Logistics Network: Efficient shipping and a robust supply chain make China a reliable choice for timely deliveries.

2. Vietnam: The Rising Contender

Vietnam is quickly becoming a significant player in the backpack manufacturing sector:

- Cost-Effective Alternative: With rising production costs in China, many brands are shifting to Vietnam for its cost-effectiveness and growing manufacturing capabilities.

- Trade Advantages: Vietnam benefits from favorable trade agreements with major markets, making it an attractive option for exporting goods.

3. Bangladesh: Budget-Friendly Production

Bangladesh is known for its cost-effective manufacturing solutions:

- Low Labor Costs: The lower cost of labor in Bangladesh allows for competitive pricing, particularly for budget-friendly backpack options.

- Growing Industry: The country’s rapidly developing manufacturing sector is increasingly able to handle diverse production needs.

4. India: Versatile and Emerging

India offers versatility and potential in the backpack industry:

- Diverse Production Capabilities: India can produce a wide range of backpacks, from high-end designs to more economical options.

- Expanding Infrastructure: Investments in infrastructure are improving India’s manufacturing efficiency and product quality.

Conclusion

Each country has its unique advantages in backpack manufacturing. China remains a top choice due to its advanced facilities, cost efficiency, material diversity, and strong logistics network. However, Vietnam, Bangladesh, and India also offer valuable benefits, such as cost savings, trade advantages, and growing production capabilities. Understanding these options can help brands make informed decisions based on their specific needs and goals.